Understanding the Oxy Gas Welding Kit

The oxy gas welding kit is a foundational tool in metal fabrication and repair techniques. It’s widely recognized for its versatility and effectiveness in various welding applications, from small DIY projects to heavy industrial repairs. In essence, this welding kit utilizes a combination of oxygen and acetylene gases to produce a flame hot enough to melt and fuse metals, making it an essential asset for both hobbyists and professionals alike.

Components of the Oxy Gas Welding Kit

A typical oxy gas welding kit comprises several essential components:

- Oxygen and Acetylene Cylinders: These are the most critical components, providing the necessary gases for welding.

- Regulators: Used to control the pressure of the gases flowing from the cylinders. Proper adjustment is crucial for maintaining a stable flame.

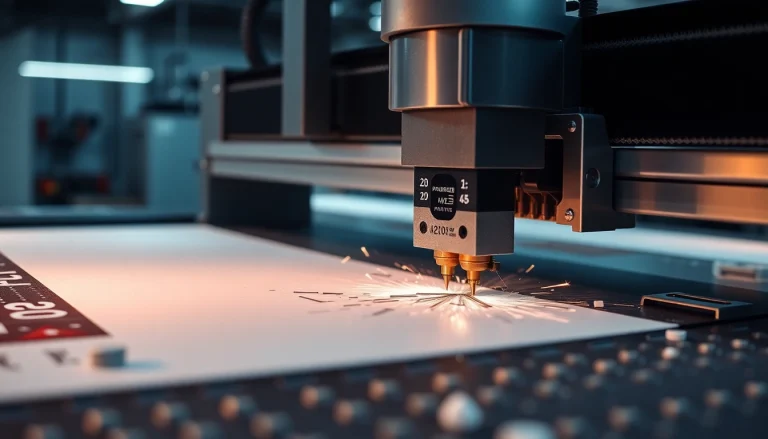

- Welding Torch: This is where the gases mix and ignite, producing the welding flame. Various nozzles can be attached for different welding tasks.

- Hoses: Typically made from rubber or another durable material, these hoses transport the gases from the cylinders to the torch.

- Fittings and Adapters: These components ensure that the hoses connect securely to the cylinders and torch.

- Safety Gear: Essential for protecting the welder, this can include gloves, goggles, and flame-resistant clothing.

Understanding each component’s role is essential for effective and safe operation of the welding kit.

Safety Precautions When Using the Oxy Gas Welding Kit

Safety should always be the top priority when using an oxy gas welding kit. Here are some vital safety precautions:

- Proper Ventilation: Ensure the workspace is well-ventilated to avoid the accumulation of hazardous gases.

- Protective Gear: Always wear safety glasses, gloves, and appropriate clothing to protect against burns and other injuries.

- Cylinder Storage: Store gas cylinders upright and secure them to prevent tipping. Keep them away from heat sources.

- Check for Leaks: Regularly inspect hoses, fittings, and connections for leaks using a soap solution. If bubbles form, there’s a leak that needs addressing.

- Know Emergency Procedures: Be familiar with first aid and emergency procedures, including how to extinguish fires or handle gas leaks.

Benefits of Using an Oxy Gas Welding Kit

The oxy gas welding kit presents numerous advantages:

- Versatility: Suitable for various tasks including welding, cutting, and heating.

- Portability: Many kits are designed to be portable, allowing for use in diverse locations.

- Cost-Effectiveness: Comparatively lower initial costs than some modern welding technologies.

- Control Over Heat: The welder has direct control over the flame and heat input, critical for intricate work.

Setting Up Your Oxy Gas Welding Kit

Essential Tools for Effective Welding

In addition to the components of the oxy gas welding kit, several tools enhance the welding experience:

- Welding Pliers: For gripping and holding welding rods.

- Welding Goggles: Essential for eye protection during welding tasks.

- Flame-Resistant Blanket: Useful for covering flammable materials in the work area.

- Measurement Tools: Rulers and calipers help ensure precise cuts and welds.

- Sparking Lighter: For igniting the torch flame safely.

Step-by-Step Setup Guide

Setting up your oxy gas welding kit requires careful attention to detail. Follow these steps:

- Place the Cylinders: Position the oxygen and acetylene cylinders in an upright and secure manner.

- Connect Hoses: Attach the hoses to the respective regulators and check the fittings for security.

- Attach Regulators: Firmly connect the regulators to the cylinders, ensuring the O2 and C2H2 are correctly matched.

- Check for Leaks: Use a soap solution to check for any leaks at the connections.

- Set Up the Torch: Connect the hose to the welding torch and securely attach the nozzle.

- Adjust Pressure: Open the cylinder valves slowly and adjust the regulator pressures according to the required specifications.

- Ignite the Torch: Use a spark lighter to ignite the gas at the torch end, adjusting the flame as necessary.

Common Setup Mistakes to Avoid

Beginner welders often make several common setup mistakes. Here are some to watch out for:

- Improper Cylinder Handling: Always transport and handle cylinders with care, ensuring correct valve protection.

- Forgetting to Check for Leaks: Never skip this vital step—small leaks can cause serious accidents.

- Incorrect Regulator Adjustment: Setting pressure too high can be dangerous; always refer to the recommended settings.

- Overlooking Protective Gear: Failing to wear safety gear increases the risk of injuries significantly.

Techniques for Using the Oxy Gas Welding Kit

Basic Welding Techniques

When starting with oxy-gas welding, mastering basic techniques is crucial:

- Joint Preparation: Clean the edges of the metal pieces to be joined, removing rust, oil, and debris for better adhesion.

- Welding Angle: Hold the torch at a 30-degree angle for optimal control over the weld.

- Filling Technique: Move the torch in a steady motion, maintaining an even pace to ensure consistency in the weld puddle.

- Adjust Flame Size: Depending on the material, adjust the flame to either a neutral position or slightly oxidizing for better penetration.

Advanced Welding Skills

For those looking to refine their skills, here are some advanced techniques:

- Tack Welding: Used to hold pieces together before completing the weld.

- Weaving Technique: Ideal for wider seams; create a weaving pattern with your torch for deeper penetration and stronger joints.

- Multi-Pass Welding: For thicker materials, applying multiple smaller welds rather than one thick bead enhances strength.

Maintenance Tips for Best Performance

Maintaining your oxy gas welding kit ensures safety and efficiency:

- Regular Inspections: Routinely check tanks, hoses, and fittings for wear or damage.

- Clean Connections: Ensure that all connections are free from dirt and debris; clean as necessary.

- Store Properly: Store cylinders upright and secure in a cool, dry place to prevent rust and corrosion.

- Replace Worn Parts: If any part of the kit is damaged or worn, replace it promptly to maintain safe operation.

Applications of the Oxy Gas Welding Kit

Industrial Uses and Applications

The oxy gas welding kit is applied in various industrial sectors, including:

- Metal Fabrication: Used extensively for constructing and modifying machinery and equipment.

- Automotive Repair: Ideal for welding components in vehicles, particularly for repair work.

- Shipbuilding: Used for both welding and cutting metal components in ship construction and repair.

DIY Projects Using the Oxy Gas Welding Kit

For enthusiasts, the oxy gas welding kit opens doors to countless DIY possibilities:

- Furniture Making: Create custom metal furniture pieces using welding techniques.

- Art and Sculpture: Artists often employ oxy-gas welding to join metal elements in their creations.

- Home Repair: Use the kit for various home metalwork repairs, from railings to structural supports.

Repair and Maintenance Scenarios

The oxy gas welding kit excels in repair scenarios that require precision and control:

- Pipe Repairs: Ability to weld or cut metal pipes efficiently, making it a suitable choice for plumbing and industrial applications.

- Machinery Maintenance: Fixing or reinforcing metal parts on machinery to extend their life and functionality.

- Metal Artwork Restoration: Repairing sculptures and metal art pieces, restoring their integrity without compromising aesthetics.

Choosing the Right Oxy Gas Welding Kit for You

Factors to Consider When Purchasing

Selecting the right oxy gas welding kit involves assessing several key factors:

- Usage Frequency: Determine whether the kit will be used for occasional tasks or heavy-duty industrial work.

- Material Types: Consider the types of metals you will primarily be working with; different kits may be better suited for specific materials.

- Portability: If you need to move the kit often, choose a lightweight and compact option.

- Budget: Establish a budget that fits your needs without compromising safety and efficiency.

Comparing Popular Models

When comparing different models of oxy gas welding kits, consider aspects like:

- Flow Rate: Higher flow rates can facilitate faster welds, but ensure it matches your intended use.

- Build Quality: Look for durable materials and well-constructed components to ensure longevity of the kit.

- Brand Reputation: Trusted brands often provide warranties and customer service that can be beneficial.

Cost Considerations and Budget Options

Oxy gas welding kits vary widely in price, starting from around $99 to over $500 depending on the complexity and included components:

- Entry-Level Kits: Generally affordable, these are suitable for beginners taking on light projects.

- Mid-Range Models: Provide a balance of quality and price, ideal for hobbyists and tradespeople.

- Professional Kits: These kits are built for heavy-duty use and include advanced features, but they come at a higher cost.

+ There are no comments

Add yours